Index >> PRODUCT >> Maize milling machine HDFM100 MAIZE MILL LINE

This is our 80t maize milling machine,100t maize milling machine design.

Maize milling machine can processing 3 kinds of maize products, sifter super white maize meal, partly sifted flour, whole meal.

We have one set 90t maize milling machine running in Zimbabwe.

One set 100t/24h maize milling machine running in South Africa and India.

According different country different market,the maize milling machine produce different final products.

This maize milling machine also complete automatic line.With cleaning-milling-packing systems.Use the stainless steel pipes and cyclone for life

long and durable.

Click here for maize milling machine running video:

https://2495557431.wistia.com/medias/h6b0thebxl

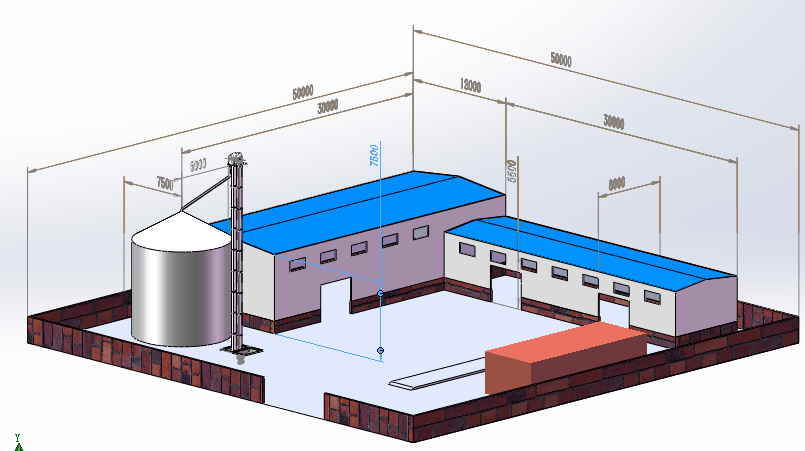

HDFM100 MAIZE MILLING MACHINE: DESIGN FOR ONE CLIENT

TOTAL LAND: 50M*50M

MAIZE MILL FACTORY MAIZE SILO: 500T

WORKSHOP BUILIDNG OF MAIZE MILLING LINE: 30M*18M*7.5M

STORE ROOM: 30M*8M*5.5M

Does the Maize Milling Factory Land can be different?

Yes, the factory land can be different according the client land details, the length and width can adjust normally, but the length of the land minimum 30meter, and the width of the land minimum 8meter.

Does the Height of the Maize mill building can be different?

The height of the building minimum 7.5meter

Does this maize milling machine can produce maize grits and maize flour same time ?

Yes, this maize milling machine can produce different kind maize product same time

Does this maize milling machine can take the germ out and press cooking oil?

Yes, this maize milling machine can separate the germ out and by the oil press machine can make the cooking oil

How about your machine warranty ?

2years, and oversea engineer can supply the maintain service

The core technologies of our group are in the filed of wheat flour mill and maize milling machine engineering, with European technology, South Africa corn process, China wheat process, roll out unique and innovative wheat flour and corn flour processing line.

High Standard Quality corn mill machine

Advance roller stands

Screw air compressor

Stainless steel pipe where contact with the material

1. Roller Mills

1) The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls. This makes residue-free cleaning possible.

2) a pulse generator automatically adjust the feed material at the entrance door

2. Roller: Two different alloys with a mixing ratio allow the perfect balance to be achieved between hardness and roughness.

3. Degerminator:

dry degermination with low fat content.

Multi-faceted sieve tube design, the screen The high-quality stainless steel nitriding treatment

4. Dampener:

Stainless steel. Bi-directional screw, Prevent free water, an intensive Intermixing

Second condition is spring dampener which give the maize surface moisture to insure

The maize can be easily degerminated

5.Bucket elevator and conveyor

with reducer, High-quality carbon steel painting

6. PIPE: stainless steel in milling section,long life and durable

7. Moisture bin: stainless steel long life and durable

8. Plant Control System: PLC CONTROL computer operate, from the computer can see all the machine running details, and can operate all the machine, from the computer screen can see the output everyday, and it show the extraction rate.

9. Dedusting system: High Energy and efficient blower Roots Blower work with air-jet dust filter, dust content<10mg/m3

10. Air system, the belt screw compressor keep stable, clean, dry air for the roller mill and packing machine

11. Auto-Weight and packing system, one for 5-10kg;one for 10-25kg, one for 100kg. The packing machine Can be choosed by the client.

12. Vitamin or Mineral Doser: Can put vitamin and mineral in CORN flour

MESSGES

PRODUCT LIST

ADD:Zanhuang, Shijiazhuang,China

TEL:0086-311-85528086

24H MOBILE: +86-13673118218

Email: topflourmill@gmail.com